KEY FEATURES OF DIAMOND DRILLING

CONTACT ROBORE FOR YOUR DIAMOND DRILLING REQUIREMENTS

Free Advice From Our Friendly And Experienced Staff

What is Diamond Drilling?

Diamond core drilling uses a rig mounted rotary drill fitted with a specialist cylindrical drill bit. The drill bit has diamond segments welded to its cutting surface. Due to their extreme strength diamonds are ideal for cutting into solid surfaces including reinforced concrete, masonry, tile, stone and asphalt.

Diamond drilling is ideal for creating, or ‘coring’, clean, precise holes ranging from 10mm and 1,500mm+ in diameter in hard materials such as stone, brick and concrete walls or other materials. Diamond drilling is commonly used in construction and controlled demolition. It offers many advantages over conventional drilling methods, as it is accurate, efficient and non-percussive.

How does Diamond Drilling work?

Diamond drilling systems are comprised of a mounted rig, electric, air or hydraulic powered drill, and diamond bit. The diamond drill bit is cylindrical and hollow, consisting of a steel tube on which diamond segments are welded to the cutting edge. These make contact with the surface being drilled.

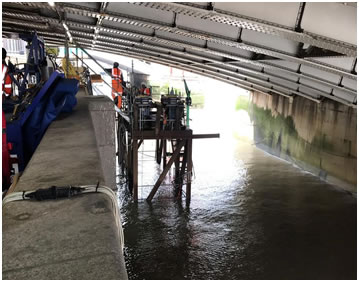

During drilling, the diamond bit rotates. Water runs through the driving shaft to cool the barrel and flush away the material being cut. Dry diamond core drilling services are available, please Contact Us to learn more.

Diamond drilling systems usually include 110v powered motors, but can also be 415v, hydraulic and or air driven systems.

Factors that need to be considered during diamond drilling include:

- Type of material/surface to be cut

- Diameters and depths of holes to be drilled

- Structural resistance of the material

This will influence the equipment required to carry out the work. Our dedicated logistics team have over three decades of experience in the industry, designing bespoke diamond drilling and concrete cutting solutions for our extensive client base. Don’t hesitate to get in touch with your enquiry today.

What is Diamond Drilling used for?

Diamond drilling can be used to create holes in a wide array of solid materials such as concrete, masonry, metal, glass, tile and stone. It has many applications within the demolition, construction, and underground industries.

Diamond Stitch Drilling

Diamond drill bits range from 10mm to 1500mm in diameter. In some cases, a larger area may need to be drilled. In this case, a technique called diamond stitch drilling is the ideal solution.

Diamond stitch drilling can be used to create openings of any shape and size. This involves drilling a series of precise, overlapping holes to create the desired opening.

CALL OUR TEAM TODAY FOR A FREE COMPREHENSIVE QUOTE AND EXPERT ADVICE

We offer diamond core drilling services at the most competitive rates,

contact us for a FREE no obligation quote TODAY.

Why use Robore?

London and the UK’s leading Diamond Drilling contractor.

Robore Cuts are the UK’s leading Diamond Drilling contractor. We have always been a company that embraces new and advanced technologies and were early to identify the potential in Diamond Drilling to become a widely sought after service throughout the construction industry and have since dedicated ourselves to mastering and pioneering this skilful technique. We provide bespoke concrete cutting, demolition and passive fire protection services to our extensive client base, which spans the public and private sectors.

Robore ensure the highest industry standards on every project. We have:

- 30 + years of experience

- 100 + highly trained staff

- Strict health and safety procedures

- State of the art equipment, including Europe’s largest fleet of Brokk & Husqvarna robotic demolition machines

Our Expertise

Our expertise is unmatched. Established in 1986, Robore are one of the most established diamond drilling & concrete cutting companies in the UK giving us more than three decades of market experience and solutions. We ensure the highest industry standards are met on every project and have the following:

- Over 150 years of combined senior management experience within the industry

- 100 + highly trained staff and operatives

- Strict health and safety procedures

- Free site surveys and specialist advice

- State of the art equipment, including Europe’s largest fleet of Brokk & Husqvarna robotic demolition machines

- An unrivalled reputation for delivering demolition projects safely on time and on budget

Certifications and Accreditations

The Robore Promise

Over 150 + years of combined managerial experience

We use the Latest & Most Advanced Equipment

Accredited to the Highest Industry Standards

London’s Leading Service Supplier to the Construction Industry