Diamond Drilling – Test core holes and wire feed holes

Wiresawing – Vertical wiresaw cutting of wall

Brokk demolition – Demolition of cut sections of wall

Drilling and Bursting – Removal of section of foundation

Background

Phase 1

Robore Cuts Ltd were initially engaged as Principal Contractor, working directly for Crossrail to carry out core holes as part of a survey of the existing basement walls and foundations.

Phase 2

Following the surveys the station box was designed. It was decided that the basement wall to the station was impeding the required design and would need to be cut to an new line along it’s length.

Requirement:

Phase 1

In the Crossrail Departures Road Scheme, the passenger access link between the proposed Crossrail station and the existing Paddington Main Line station has been proposed via the Block-C building of MacMillan House. The proposed works associated with the new link were being designed with extreme caution, to avoid any adverse impact/ damage to the existing Grade I listed building including the Brunel shed and the historical arcade along Platform 1 of Paddington Station. Intrusive surveys were required to the Block-C building in order to understand the existing structural configuration/ layout and design temporary and permanent structural works for the Departures Road Scheme.

Phase 2

Reducing the width of the existing basement wall

Constraints and Challenges

Cutting the wall to the level of accuracy required, without compromising the wall’s structural integrity or the safety of operatives.

Techniques and Hardware Used

Phase 1 works were carried out whilst the station was closed and detailed core logs drawn up for the design team detailing the depth, type of material drilled etc.

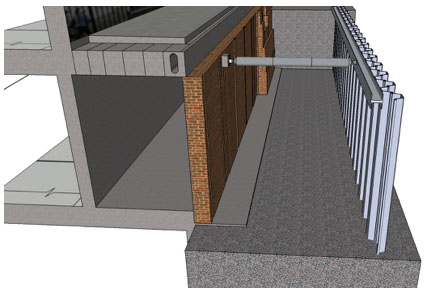

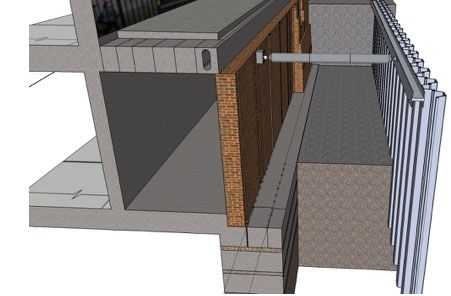

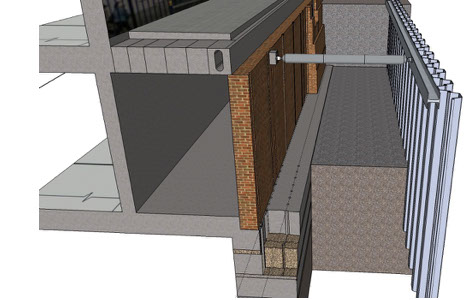

Phase 2 works were carried out with the station in full operational mode. Several techniques were explored including stitch drilling from ground level down to the required depth, plunge wiresawing from ground floor level. Through the use of 3D modelling each technique was explored and the pros and cons assessed.

The technique that fitted best with the client’s and H&S requirements was to wiresaw the wall in sections to the required line from the base of the wall and then peeling the cut section away using a brokk. The wall foundation was then drilled and burst.

The sequence of work was as follows:

Temporary works installed and ground excavated to expose the wall by others.

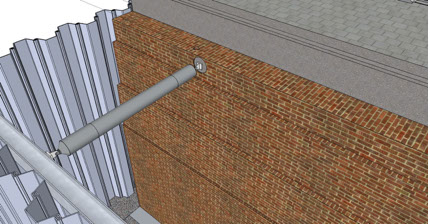

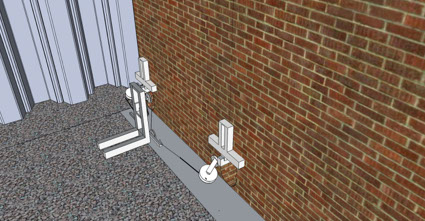

Holes drilled to the base of the wall, these intersect with vertical holes drilled on the cut line down to the top of the foundation. Guide pulleys were inserted into the holes, fixed into position and the wire fed up one hole, across the top of the wall and down the other.

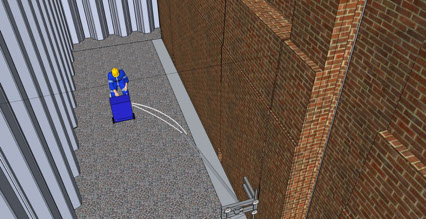

The wiresaw was set up between the guide pulleys and the wire was drawn downwards cutting through the wall.

Vertical cuts were made perpendicular to the line of the wall using the wiresaw and the vertical wire feed holes to section the wall. All cuts were made with the operatives working remotely at a safe location.

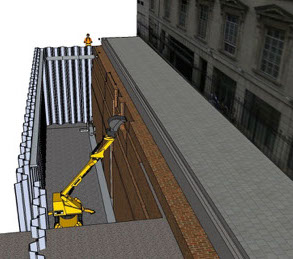

The wall was then peeled off using a brokk remotely controlled machine.

Bursting holes were drilled vertically into the foundation.

The concrete was burst and removed using a brokk.

Conclusion:

Robore used 3D modelling to test out several options for the works enabling us to plan, execute and complete the works using the safest, most efficient and accurate methods.

The Robore Promise

Over 150 + years of combined managerial experience

We use the Latest & Most Advanced Equipment

Accredited to the Highest Industry Standards

London’s Leading Service Supplier to the Construction Industry